Intellistat Ion Air Nozzle

A mountable nozzle for hands free static elimination at assembly stations and benchtop applications!

Rated Class 5 for clean rooms and controlled environments per ISO 14644-1

Rated Class 5 for clean rooms and controlled environments per ISO 14644-1

What is the Intellistat Ion Air Nozzle?

The patent pending Model 8505 Intellistat Ion Air Nozzle is EXAIR’s latest hands-free innovation in a long line of static elimination solutions. This intelligent product provides a balanced ionized air stream to neutralize static and remove troublesome particulate during sensitive assembly work, test procedures and clean processes. With a +/-30 volt off set, the Intellistat nozzle was designed to use minimal compressed air while delivering a focused blowoff and exceptional static decay rates capable of reducing 1000 volts to 100 volts in 0.6 seconds. e design includes an efficient, low voltage transformer which converts 120VAC to 24V DC to assure safety. An EXAIR engineered air nozzle delivers the air well below the OSHA standards for noise exposure and dead-end pressure, which maintains safety compliance.

Why the Intellistat Ion Air Nozzle?

Including a compact stainless steel adjustable mounting bracket, the Intellistat nozzle can be mounted to benchtops and machine frames, for example, to provide hands-free operation when needing both hands to package, test or assemble parts and products. The Intellistat Ion Air Nozzle is designed with other convenient features including the 6mm push-in air connection, and green and red LEDs which indicate proper functionality. The housing is made of a durable static dissipative polycarbonate to further minimize any potential for static electricity discharge around sensitive electronics, sensors or materials. The Intellistat Ion Air Nozzle produces an ionized airstream that is essential for removing static, dust, debris and particulate in sterile environments such as pharmaceutical and medical laboratories, clean rooms and electronics labs.

Applications

• Precision parts assembly

• Maintain charge neutrality in laboratory processes

• Remove particles from parts and surfaces in clean environments

• PCB manufacturing

• Maintain cleanliness during electronics manufacturing, assembly and testing

• Eliminate electrostatic discharge

• Remove debris from medical products

• Clean lenses, glass containers and slides

Advantages

•Mountable, hands-free operation

•Quick change emitter point

• Rapid static decay

• Low voltage operation

• OSHA safe air outlet and noise level

• LED indicators for proper and improper functionality

•Quick change emitter point

• Rapid static decay

• Low voltage operation

• OSHA safe air outlet and noise level

• LED indicators for proper and improper functionality

How The Intellistat Ion Air Nozzle Works

Intellistat Ion Air Nozzle Specications

Certications: The Intellistat Ion Air Nozzle is UL listed and CE and RoHS compliant. Power Supply Input: 100-240VAC - 50/60 Hz 0.7A Max

Power Supply Output: EXAIR Model 902067 Power Supply (24VDC, 1.0A Max) is required for Intellistat Ion Air Nozzle operation. Included with Intellistat Ion Air Nozzle.

Electrical Hazard: Shockless (less than 40 microamperes short circuited)

Do not use near flammable materials or gases.

Balance: ±30V

Operating Temperature: 32°F to 105°F (0-41°C)

Do not use near flammable materials or gases.

Materials of Construction:

Plastic Parts: Static Resistant Polycarbonate

Emitters: Stainless Steel Gas

Input: 30psig - 125psig

Clean Dry Compressed Air or Nitrogen

Air Connection: 6mm tube

Cleanroom Classification: ISO 14644-1 Class 5, operational. 6mm tubeNPT inlet provided.

Power Supply Output: EXAIR Model 902067 Power Supply (24VDC, 1.0A Max) is required for Intellistat Ion Air Nozzle operation. Included with Intellistat Ion Air Nozzle.

Electrical Hazard: Shockless (less than 40 microamperes short circuited)

Do not use near flammable materials or gases.

Balance: ±30V

Operating Temperature: 32°F to 105°F (0-41°C)

Do not use near flammable materials or gases.

Materials of Construction:

Plastic Parts: Static Resistant Polycarbonate

Emitters: Stainless Steel Gas

Input: 30psig - 125psig

Clean Dry Compressed Air or Nitrogen

Air Connection: 6mm tube

Cleanroom Classification: ISO 14644-1 Class 5, operational. 6mm tubeNPT inlet provided.

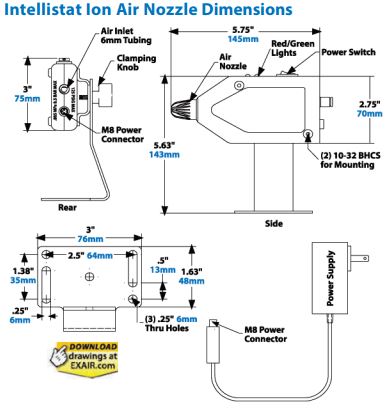

After connecting the 24V power supply, activate the power switch (1) and turn on a compressed source to supply the 6mm push-in tting (2) to activate the static eliminating ions and airflow. Proper or improper functionality is indicated by a green or red LED (3). The non-marring nozzle (4) provides quiet performance and OSHA compliance. The compact mounting bracket (5) is included to provide handsfree operation.