EXAIR's 1/8FNPT and 1/4 FNPT siphon fed flat fan pattern nozzles are great where no liquid pressure is available and a thin coating is needed over a wide band. Flow rate is adjustable via the adjusting valve. Siphon nozzles work best with a suction height of 36" (914mm) or less. Since these nozzles are siphon fed, the compressed airflow draws the liquid in and mixes it internally. Liquid flow is dependent both on the gravity or suction height and the airflow. Siphon fed flat fan pattern nozzles are the best choice where liquid is needed over a broad band such as a moving assembly line.

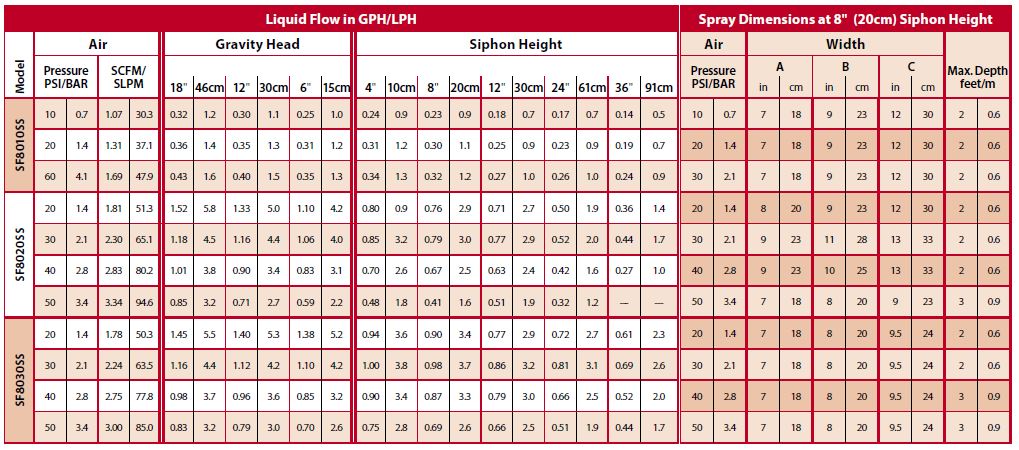

Siphon or gravity fed for non-pressurized applications.Siphon Fed Flat Fan Pattern - 1/8 NPT

Model SF8010SS, SF8020SS and SF8030SS

1/8 NPT siphon fed flat fan pattern nozzles are great where no liquid pressure is available and a thin coating is needed over a wide band. Flow rate is adjustable via the adjusting valve. Siphon nozzles work best with a suction height of 36" (914mm) or less. Since these nozzles are siphon fed, the compressed airflow draws the liquid in and mixes it internally. Liquid flow is dependent both on the gravity or suction height and the airflow. Siphon fed flat fan pattern nozzles are the best choice where liquid is needed over a broad band such as a moving assembly line.

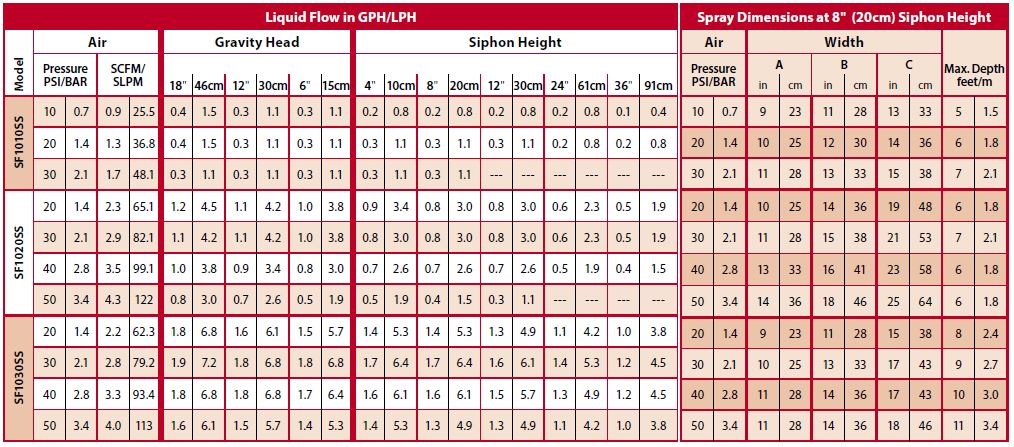

Siphon Fed Flat Fan Pattern - 1/4 NPT

Model SF1010SS, SF1020SS and SF1030SS

1/4 NPT siphon fed flat fan pattern nozzles are great where no liquid pressure is available and a thin coating is needed over a wide band. Flow rate is adjustable via the adjusting valve. Siphon nozzles work best with a suction height of 36" (914mm) or less. Since these nozzles are siphon fed, the compressed airflow draws the liquid in and mixes it internally. Liquid flow is dependent both on the gravity or suction height and the airflow. Siphon fed flat fan pattern nozzles are the best choice where liquid is needed over a broad band such as a moving assembly line.