Standard Air Knife

Hard hitting curtain of air for web, sheet and part blowoff .

A quiet, energy efficient way to clean, dry or cool parts, webs or conveyors. The Standard Air Knife utilizes the Coanda effect (wall attachment of a high velocity fluid) to create air motion in its surroundings. Using a small amount of compressed air as a power source, the Standard Air Knife pulls in large volumes of surrounding air to produce a high flow, high velocity curtain of air for blowoff .

Why the Standard Air Knife?

Amplification ratios (entrained air to compressed air) of 30:1 are achieved with the Standard Air Knife, compared to 3:1 for drilled or slotted pipe. Air savings of 40% to 90% are possible when replacing these "homemade" blowoff devices. Pay-back is normally measured in weeks, not months or years. The Standard Air Knife dramatically reduces "wind shear" by gradually introducing the entrained air to the ejected compressed air. Noise level is typically cut in half. The result is a high velocity, high volume sheet of air with reduced noise level and air consumption. Drilled pipe or open jets, by contrast, provide minimal air amplification. They also produce unacceptably high noise levels as the compressed air shears into the still air.

A Model 2012 12" (305mm) Standard Air Knife opens mustard packets prior to fill.

Applications

• Sheet cleaning in strip mills

• Conveyor cleaning

• Web drying or cleaning

• Part or component cooling

• Environmental separation

• Pre-paint blowoff

• Bag opening/fill operations

• Scrap removal on converting operations

Advantages

• Reduced air consumption

• 30:1 air amplification

• Aluminum or stainless steel

• Compact, rugged, easy to install

• Stock lengths to 48" (1219mm)

• No moving parts

• Compressed air inlets on each end

• Variable force and flow

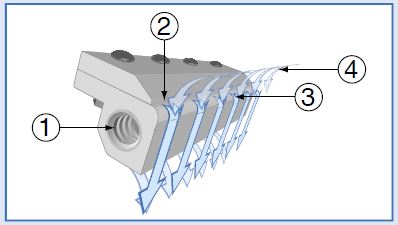

How The Standard Air Knife Works

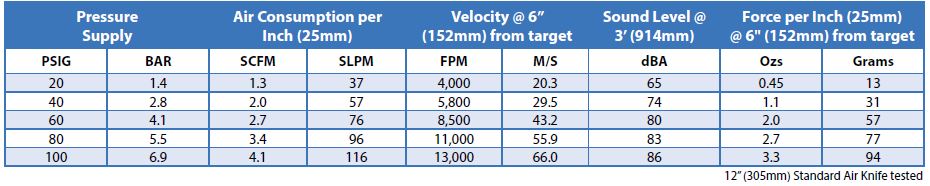

Standard Air Knife Performance with .002" (0.05mm) thick shim installed

Standard Air Knife Specifications

Compressed Air Inlets: A Standard Air Knife has compressed air inlets on each end. Lengths 24" (610mm) and longer should be supplied with compressed air at each end to maintain uniform airflow.

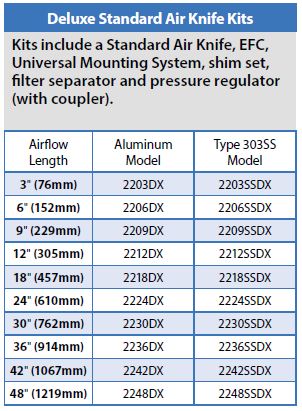

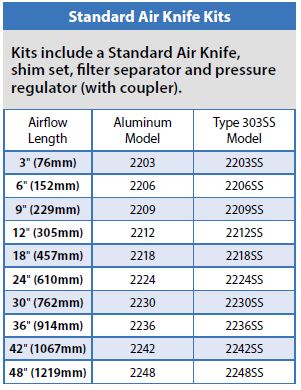

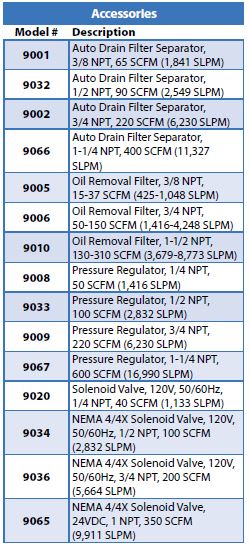

Filtration: The use of clean air is essential. Kits include an automatic drain filter with a 5 micron filter element that is sized properly for flow.

Materials of Construction: The Standard Air Knife is available in either aluminum or stainless steel construction.

Mounting: Universal Air Knife Mounting System. The Standard Air Knife can also be supported by the compressed air pipe.

Regulation: A pressure regulator on the compressed air supply provides infinite control of flow, force, and air consumption. Kits include a pressure regulator that is sized properly for flow.

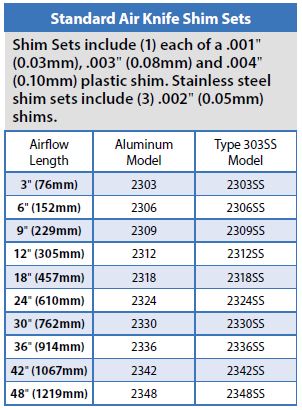

Shim Sets: A Standard Air Knife has a .002" (0.05mm) gap setting. This gap is set with a shim positioned between the cap and body of the Standard Air Knife. Force and flow through the Standard Air Knife may be easily increased by adding shims to open the gap. Standard Air Knife Kits include a shim set (three additional shims). Shim sets for aluminum Standard Air Knives include a .001" (0.03mm) Amber color , .003" (0.08mm) Green color , and .004" (0.10mm) thick Tan color plastic shims. Shim sets for stainless steel Standard Air Knives include (3) .002" (0.05mm) thick stainless steel shims.