Light Duty Line Vac

What Is The Line Vac?

A fast, low cost way to convey:

Plastic pellets, Scrap trim, Textiles, Bulk solids, Food products, Chips, Paper , Pills/tablets, Small parts, Shavings, Sawdust and Granules etc.

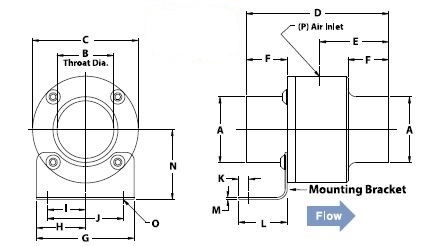

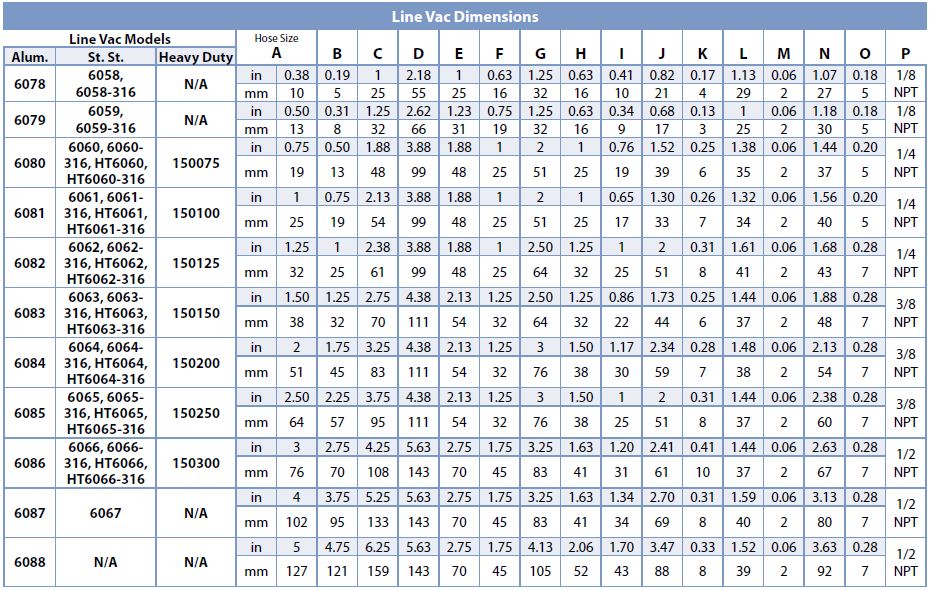

EXAIR's compressed air operated Line Vac connects to standard hose or tube to create a powerful in-line conveyor. The compact design features large throat diameters for maximum throughput capacity. Eleven sizes in aluminum and ten sizes in stainless steel are suited to a wide variety of transfer applications. (A Model 6080 3/4" (19mm) Line Vac vacuums plastic as it is drilled.)

Why The Line Vac?

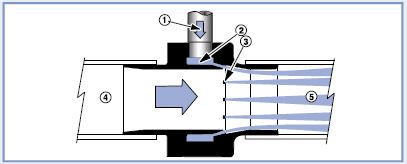

Line Vac conveyors are ideal for moving large volumes of material over long distances. A small amount of compressed air is injected through directed nozzles to produce a vacuum on one end and high output flows on the other, with instantaneous response. The material flow rate is easily controlled with a pressure regulator. An optional bracket permits easy mounting. No moving parts or electricity assures maintenance-free operation. (The Model 6083 1 1/2" (38mm) Line Vac conveys plastic granules to the gravity feed hopper on an extruder.)

Applications

• Hopper loading

• Fiber tensioning

• Material conveying

• Waste/trim removal

• Chip removal

• Part transfer

• Filling operations

Advantages

• Quiet

• No moving parts

• Fits standard hose or tube

• Aluminum or stainless steel

• Eleven sizes

• High throughput capability

How The Line Vac Works

Line Vac Conveying Rates