Vortex Tube

A low cost, reliable, maintenance free solution to a variety of industrial spot cooling problems. Using an ordinary supply of compressed air as a power source, vortex tubes create two streams of air, one hot and one cold, with no moving parts. Vortex tubes can produce:

• Temperatures from -50° to +260°F (-46° to +127°C)

• Flow rates from 1 to 150 SCFM (28 to 4,248 SLPM)

• Refrigeration up to 10,200 Btu/hr. (2,570 Kcal/hr.)

Temperatures, flows and cooling power are adjustable over a wide range using the control valve on the hot end exhaust.

EXAIR Vortex Tubes are constructed of stainless steel. The wear resistance of stainless steel, as well as its resistance to corrosion and oxidation, assures that EXAIR Vortex Tubes will provide years of reliable, maintenance-free operation.

• Temperatures from -50° to +260°F (-46° to +127°C)

• Flow rates from 1 to 150 SCFM (28 to 4,248 SLPM)

• Refrigeration up to 10,200 Btu/hr. (2,570 Kcal/hr.)

Temperatures, flows and cooling power are adjustable over a wide range using the control valve on the hot end exhaust.

EXAIR Vortex Tubes are constructed of stainless steel. The wear resistance of stainless steel, as well as its resistance to corrosion and oxidation, assures that EXAIR Vortex Tubes will provide years of reliable, maintenance-free operation.

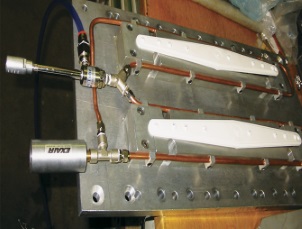

A Model 3225 Vortex Tube keeps plastic dishwasher arms cool during ultrasonic welding.

Special high temperature vortex tubes keep a boroscope lens cool while inserted into a 1200°F (650°C) boiler porthole.

A pair of medium vortex tubes cool a solenoid coil after a welding operation.

Applications

• Cooling electronic controls

• Cooling machining operations

• Cooling CCTV cameras

• Setting hot melts

• Cooling soldered parts

• Cooling gas samples

• Electronic component cooling

• Cooling heat seals

• Cooling environmental chambers

• Cooling machining operations

• Cooling CCTV cameras

• Setting hot melts

• Cooling soldered parts

• Cooling gas samples

• Electronic component cooling

• Cooling heat seals

• Cooling environmental chambers

Advantages

• No moving parts

• No electricity or chemicals

• Small, lightweight

• Low cost

• Maintenance free

• Instant cold air

• Durable - stainless steel

• Adjustable temperature

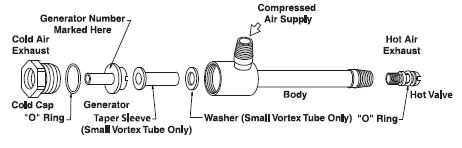

• Interchangeable generators

• No electricity or chemicals

• Small, lightweight

• Low cost

• Maintenance free

• Instant cold air

• Durable - stainless steel

• Adjustable temperature

• Interchangeable generators

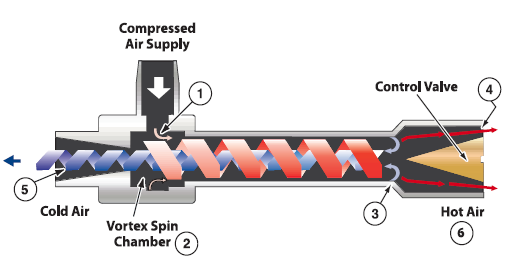

How A Vortex Tube Works

Compressed air, normally 80-100 PSIG (5.5 - 6.9 BAR), is ejected tangentially (1) through a generator into the vortex spin chamber (2). At up to 1,000,000 RPM, this

air stream revolves toward the hot end (3) where some escapes through the control valve (4). The remaining air, still spinning, is forced back through the center of this outer vortex. The inner stream gives off kinetic energy in the form of heat to the outer stream and exits the vortex tube as cold air (5). The outer stream exits the opposite end as hot air (6). There is a detailed discussion of vortex tube history and theory later on page 180 in this section.

air stream revolves toward the hot end (3) where some escapes through the control valve (4). The remaining air, still spinning, is forced back through the center of this outer vortex. The inner stream gives off kinetic energy in the form of heat to the outer stream and exits the vortex tube as cold air (5). The outer stream exits the opposite end as hot air (6). There is a detailed discussion of vortex tube history and theory later on page 180 in this section.

Controlling Temperature And Flow In A Vortex Tube

Cold airflow and temperature are easily controlled by adjusting the slotted valve in the hot air outlet. Opening the valve reduces the cold airflow and the cold air temperature. Closing the valve increases the cold airflow and the cold air temperature. The percentage of air directed to the cold outlet of the vortex tube is called the “cold fraction”. In most applications, a cold fraction of 80% produces a combination of cold flow rate and temperature drop that maximizesn refrigeration, or Btu/hr. (Kcal/hr.), output of a vortex tube. While low cold fractions (less than 50%) produce lowest temperatures, cold airflow volume is sacrificed to achieve them.

Most industrial applications, i.e., process cooling, part cooling, chamber cooling, require maximum refrigeration and utilize the 32XX series Vortex Tube. Certain “cryogenic” applications, i.e., cooling lab samples, circuit testing, are best served by the 34XX series Vortex Tube.

Setting a vortex tube is easy. Simply insert a thermometer in the cold air exhaust and set the temperature by adjusting the valve at the hot end. Maximum refrigeration (80% cold fraction) is achieved when cold air temperature is 50°F (28°C) below compressed air temperature.

Most industrial applications, i.e., process cooling, part cooling, chamber cooling, require maximum refrigeration and utilize the 32XX series Vortex Tube. Certain “cryogenic” applications, i.e., cooling lab samples, circuit testing, are best served by the 34XX series Vortex Tube.

Setting a vortex tube is easy. Simply insert a thermometer in the cold air exhaust and set the temperature by adjusting the valve at the hot end. Maximum refrigeration (80% cold fraction) is achieved when cold air temperature is 50°F (28°C) below compressed air temperature.

If you are unsure of your flow and temperature requirements, EXAIR recommends the purchase of an EXAIR Cooling Kit. It contains a vortex tube, cold air muffler, air line filter and all generators required to experiment with the full range of airflows and temperatures.

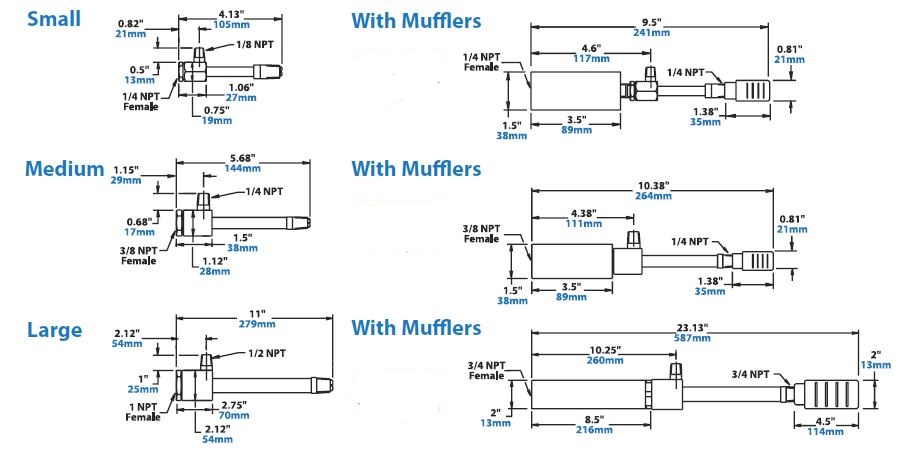

Selecting The Right Vortex Tube

EXAIR Vortex Tubes are available in three sizes. Each size can produce a number of flow rates, as determined by a small internal part called a generator. If Btu/hr. (Kcal/hr.) requirements, or flow and temperature requirements are known, simply select the appropriate vortex tube according to the specification information shown below . Keep in mind that the vortex generators are interchangeable. If, for example, a Model 3215 Vortex Tube does not provide sufficient cooling, you need only change generators within the vortex tube to upgrade the flow rate from 15 to 25, 30 or 40 SCFM (425 to 708, 850 or 1,133 SLPM).

Vortex Tube Dimensions

Vortex Tube Specifications

32XX series Vortex Tubes optimize temperature drop and airflow to produce maximum cooling power or Btu/ hr. (Kcal/hr.). Specify 32XX series Vortex Tubes for most general cooling applications.

| 32XX Series Vortex Tube Specifications | ||||||

|

Model |

SCFM* | SLPM* | Btu/hr.** |

Kcal/hr.** |

SIZE |

dBA*** |

| 3202 | 2 | 57 | 135 | 34 | Small | 68 |

| 3204 | 4 | 113 | 275 | 69 | Small | 70 |

| 3208 | 8 | 227 | 550 | 139 | Small | 76 |

| 3210 | 10 | 283 | 650 | 164 | Medium | 80 |

| 3215 | 15 | 425 | 1,000 | 252 | Medium | 81 |

| 3225 | 25 | 708 | 1,700 | 428 | Medium | 82 |

| 3230 | 30 | 850 | 2,000 | 504 | Medium | 84 |

| 3240 | 40 | 1,133 | 2,800 | 706 | Medium | 88 |

| 3250 | 50 | 1,416 | 3,400 | 857 | Large | 94 |

| 3275 | 75 | 2,124 | 5,100 | 1,285 | Large | 96 |

| 3298 | 100 | 2,832 | 6,800 | 1,714 | Large | 96 |

| 3299 | 150 | 4,248 | 10,200 | 2,570 | Large | 97 |

* SCFM (SLPM) at 100 PSIG (6.9 BAR) Inlet Pressure

** Btu/hr. (Kcal/hr.) Cooling Capacity at 100 PSIG (6.9 BAR)

*** Noise levels taken with hot and cold mufflers installed.

** Btu/hr. (Kcal/hr.) Cooling Capacity at 100 PSIG (6.9 BAR)

*** Noise levels taken with hot and cold mufflers installed.

34XX series Vortex Tubes provide lowest cold air temperatures, but at low cold airflow (when less than a 50% cold fraction is used). Specify 34XX series Vortex Tubes only where temperatures below 0°F (-18°C) are desired.

| 34XX Series Vortex Tube Specifications | ||||||

|

Model |

SCFM* | SLPM* | Btu/hr.** |

Kcal/hr.** |

SIZE |

dBA*** |

| 3402 | 2 | 57 | ----- | ----- | Small | 67 |

| 3404 | 4 | 113 | ----- | ----- | Small | 69 |

| 3408 | 8 | 227 | ----- | ----- | Small | 75 |

| 3410 | 10 | 283 | ----- | ----- | Medium | 78 |

| 3415 | 15 | 425 | ----- | ----- | Medium | 80 |

| 3425 | 25 | 708 | ----- | ----- | Medium | 82 |

| 3430 | 30 | 850 | ----- | ----- | Medium | 84 |

| 3440 | 40 | 1,133 | ----- | ----- | Medium | 87 |

| 3450 | 50 | 1,416 | ----- | ----- | Large | 93 |

| 3475 | 75 | 2,124 | ----- | ----- | Large | 96 |

| 3498 | 100 | 2,832 | ----- | ----- | Large | 96 |

| 3499 | 150 | 4,248 | ----- | ----- | Large | 96 |

* SCFM (SLPM) at 100 PSIG (6.9 BAR) Inlet Pressure

** Not Applicable. 34XX series Vortex Tubes are not normally used in air conditioning applications.

*** Noise levels taken with hot and cold mufflers installed.

** Not Applicable. 34XX series Vortex Tubes are not normally used in air conditioning applications.

*** Noise levels taken with hot and cold mufflers installed.

Vortex Tube Performance

The Vortex Tube Performance Charts below give approximate temperature drops (and rises) from inlet air temperature produced by a vortex tube set at each cold fraction. Assuming no fluctuation of inlet temperature or pressure, a vortex tube will reliably maintain temperature within ±1°F.

|

Pressure |

Cold Fraction % |

||||||

| PSIG | 20 | 30 | 40 | 50 | 60 | 70 | 80 |

| 20 | 62 | 60 | 56 | 51 | 44 | 36 | 28 |

| 15 | 25 | 36 | 50 | 64 | 83 | 107 | |

| 40 | 88 | 85 | 80 | 73 | 63 | 52 | 38 |

| 21 | 35 | 52 | 71 | 92 | 117 | 147 | |

| 60 | 104 | 100 | 93 | 84 | 73 | 60 | 46 |

| 24 | 40 | 59 | 80 | 104 | 132 | 166 | |

| 80 | 115 | 110 | 102 | 92 | 80 | 66 | 50 |

| 25 | 43 | 63 | 86 | 113 | 143 | 180 | |

| 100 | 123 | 118 | 110 | 100 | 86 | 71 | 54 |

| 26 | 45 | 67 | 90 | 119 | 151 | 191 | |

| 120 | 129 | 124 | 116 | 104 | 91 | 74 | 55 |

| 26 | 46 | 69 | 94 | 123 | 156 | 195 | |

Numbers in shaded area give temperature drop of cold air, °F. Numbers in white area give temperature rise of hot air, °F.

|

Pressure |

Cold Fraction % |

||||||

| BAR | 20 | 30 | 40 | 50 | 60 | 70 | 80 |

| 1.4 | 34.4 | 33.3 | 31.1 | 28.3 | 24.4 | 20.0 | 15.6 |

| 8.3 | 13.9 | 20.0 | 28.3 | 35.6 | 46.1 | 59.4 | |

| 2 | 40.9 | 39.6 | 37.1 | 33.8 | 29.2 | 24.0 | 18.1 |

| 9.8 | 16.4 | 24.0 | 33.3 | 42.6 | 54.6 | 69.5 | |

| 3 | 50.4 | 48.7 | 45.7 | 41.6 | 36.0 | 29.7 | 21.9 |

| 12.0 | 19.9 | 29.6 | 40.3 | 52.3 | 66.5 | 83.5 | |

| 4 | 56.9 | 54.7 | 50.9 | 46.1 | 40.0 | 32.9 | 25.1 |

| 13.2 | 21.9 | 32.4 | 43.9 | 57.1 | 72.5 | 91.2 | |

| 5 | 61.6 | 59.0 | 54.8 | 49.4 | 43.0 | 35.4 | 26.9 |

| 13.7 | 23.3 | 34.2 | 46.5 | 60.9 | 77.2 | 97.1 | |

| 6 | 65.4 | 62.7 | 58.2 | 52.7 | 45.6 | 37.6 | 28.6 |

| 14.1 | 24.3 | 35.8 | 48.6 | 63.9 | 81.0 | 102.1 | |

| 7 | 68.6 | 65.8 | 61.4 | 55.7 | 48.0 | 39.6 | 30.0 |

| 14.4 | 25.1 | 37.3 | 50.2 | 66.3 | 84.2 | 106.3 | |

| 8 | 71.1 | 68.2 | 63.8 | 57.3 | 50.0 | 40.8 | 30.4 |

| 14.4 | 25.4 | 38.1 | 51.8 | 67.9 | 86.1 | 107.9 | |

Numbers in shaded area give temperature drop of cold air, °C. Numbers in white area give temperature rise of hot air, °C.

| EXAIR Cooling Kits | |

| EXAlR Cooling Kits include a vortex tube, all generators, cold muffler, fitting, tubing and clips to duct cold air, and filter separator. | |

|

Model # |

Description |

| 3908 | Cooling Kit up to 550 Btu/hr. (139 Kcal/hr.), Small Size |

| 3930 | Cooling Kit up to 2,800 Btu/hr. (706 Kcal/hr.), Medium Size |

| 3998 | Cooling Kit up to 10,200 Btu/hr. (2,570 Kcal/hr.), Large Size |

| Vortex Tubes | |

|

Model # |

Description |

| 3202 | Vortex Tube, 2 SCFM (57 SLPM), for max. refrigeration, 135 Btu/hr. (34 Kcal/hr.), Small Size |

| 3204 | Vortex Tube, 4 SCFM (113 SLPM), for max. refrigeration, 275 Btu/hr. (69 Kcal/hr.), Small Size |

| 3208 | Vortex Tube, 8 SCFM (227 SLPM), for max. refrigeration, 550 Btu/hr. (139 Kcal/hr.), Small Size |

| 3210 | Vortex Tube, 10 SCFM (283 SLPM), for max. refrigeration, 650 Btu/hr. (164 Kcal/hr.), Medium Size |

| 3215 | Vortex Tube, 15 SCFM (425 SLPM), for max. refrigeration, 1,000 Btu/hr. (252 Kcal/hr.), Medium Size |

| 3225 | Vortex Tube, 25 SCFM (708 SLPM), for max. refrigeration, 1,700 Btu/hr. (428 Kcal/hr.), Medium Size |

| 3230 | Vortex Tube, 30 SCFM (850 SLPM), for max. refrigeration, 2,000 Btu/hr. (504 Kcal/hr.), Medium Size |

| 3240 | Vortex Tube, 40 SCFM (1,133 SLPM), for max. refrigeration, 2,800 Btu/hr. (706 Kcal/hr.), Medium Size |

| 3250 | Vortex Tube, 50 SCFM (1,416 SLPM), for max. refrigeration, 3,400 Btu/hr. (857 Kcal/hr.), Large Size |

| 3275 | Vortex Tube, 75 SCFM (2,124 SLPM), for max. refrigeration, 5,100 Btu/hr. (1,285 Kcal/hr.), Large Size |

| 3298 | Vortex Tube, 100 SCFM (2,832 SLPM), for max. refrigeration,6,800 Btu/hr. (1,714 Kcal/hr.), Large Size |

| 3299 | Vortex Tube, 150 SCFM (4,248 SLPM), for max. refrigeration, 10,200 Btu/hr. (2,570 Kcal/hr.), Large Size |

| 3402 | Vortex Tube, 2 SCFM (57 SLPM), for max. cold temperature, Small Size |

| 3404 | Vortex Tube, 4 SCFM (113 SLPM), for max. cold temperature, Small Size |

| 3408 | Vortex Tube, 8 SCFM (227 SLPM), for max. cold temperature, Small Size |

| 3410 | Vortex Tube, 10 SCFM (283 SLPM), for max. cold temperature, Medium Size |

| 3415 | Vortex Tube, 15 SCFM (425 SLPM), for max. cold temperature, Medium Size |

| 3425 | Vortex Tube, 25 SCFM (708 SLPM), for max. cold temperature, Medium Size |

| 3430 | Vortex Tube, 30 SCFM (850 SLPM), for max. cold temperature, Medium Size |

| 3440 | Vortex Tube, 40 SCFM (1,133 SLPM), for max. cold temperature, Medium Size |

| 3450 | Vortex Tube, 50 SCFM (1,416 SLPM), for max. cold temperature, Large Size |

| 3475 | Vortex Tube, 75 SCFM (2,124 SLPM), for max. cold temperature, Large Size |

| 3498 | Vortex Tube, 100 SCFM (2,832 SLPM), for max. cold temperature, Large Size |

| 3499 | Vortex Tube, 150 SCFM (4,248 SLPM), for max. cold temperature,Large Size |

| Vortex Tube Accessories and Components | |

|

Model # |

Description |

| 3905 | Cold Muffler for 2 through 8 SCFM (57 - 227 SLPM) Vortex Tube, Small Size |

| 3901 | Cold Muffler for 10 through 40 SCFM (283 - 1,133 SLPM) Vortex Tube, Medium Size |

| 3906 | Cold Muffler for 50 through 150 SCFM (1,416 - 4,248 SLPM) Vortex Tube, Large Size |

| 3903 | Hot Muffler for 2 through 40 SCFM (57 - 1,133 SLPM) Vortex Tube, Small & Medium Size |

| 3907 | Hot Muffler for 50 through 150 SCFM (1,416 - 4,248 SLPM) Vortex Tube, Large Size |

| 3909 | Generator Kit for 2 through 8 SCFM (57 - 227 SLPM) Vortex Tube, Small Size |

| 3902 | Generator Kit for 10 through 40 SCFM (283 - 1,133 SLPM) Vortex Tube, Medium Size |

| 3910 | Generator Kit for 50 through 150 SCFM (1,416 - 4,248 SLPM) Vortex Tube, Large Size |

| Generator Kits ordered with a vortex tube include all generators for the specified tube. Permits setting the vortex tube for all capacities and styles. Generator Only —Specify capacity (SCFM) and style (“R” for max. refrigeration, “C” for max. cold temperature). Example: 15-R = 15 SCFM Generator for max. refrigeration 50-C = 50 SCFM Generator for max. cold temperature |

|

| Accessories | |

|

Model # |

Description |

| 9001 | Automatic Drain Filter Separator, 3/8 NPT, 65 SCFM (1,841 SLPM) |

| 9032 | Automatic Drain Filter Separator, 1/2 NPT, 90 SCFM (2,549 SLPM) |

| 9002 | Automatic Drain Filter Separator, 3/4 NPT, 220 SCFM (6,230 SLPM) |

| 9005 | Oil Removal Filter, 3/8 NPT, 15-37 SCFM (425-1,048 SLPM) |

| 9006 | Oil Removal Filter, 3/4 NPT, 50-150 SCFM (1,416-4,248 SLPM) |

| 9015 | Valve and Thermostat Kit, 120V, 50/60Hz, 1/4 NPT, 40 SCFM (1,133 SLPM) |

Other solenoid valves and thermostats available. Contact factory.

Note: Flow ratings shown (SCFM/SLPM) assume 100 PSIG (6.9 BAR) inlet pressure. At other pressures, flow is proportional to absolute inlet pressure.

Note: Flow ratings shown (SCFM/SLPM) assume 100 PSIG (6.9 BAR) inlet pressure. At other pressures, flow is proportional to absolute inlet pressure.