Quiet, hard-hitting curtain of air for blowoff , cleaning, drying, and cooling.

What Is The Super Air Knife?

EXAIR's Super Air Knife is the latest generation of our engineered air knife that dramatically reduces compressed air usage and noise when compared to other blowoffs. The Super Air Knife offers a more efficient way to clean, dry or cool parts, webs or conveyors. It delivers a uniform sheet of laminar airflow across the entire length with hard-hitting force.

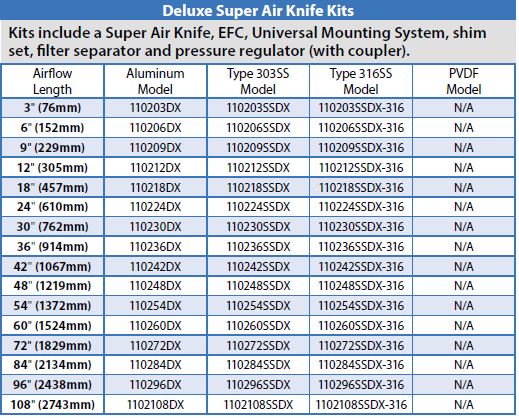

Noisy blowoffs become a whisper when replaced with the compact Super Air Knife. Even at high pressures of 80 PSIG (5.5 BAR), the sound level is surprisingly quiet at 69 dBA for most applications! Air amplification ratios (entrained air to compressed

air) of 40:1 are produced. Meets OSHA maximum dead-end pressure and noise requirements.

Applications

• Part drying after wash

• Sheet cleaning in strip mills

• Conveyor cleaning

• Part or component cooling

• Web drying or cleaning

• Environmental separation

• Pre-paint blowoff

• Bag opening/filling operations

• Scrap removal on converting operations

Advantages

•Quiet - 69 dBA for most applications

• Minimal air consumption

• 40:1 air amplification

• Uniform airflow across entire length

• Variable force and flow

• No moving parts - maintenance free

• Easy mounting - compressed air inlets

on each end and bottom

• Compact, rugged, easy to install

• Minimal air consumption

• 40:1 air amplification

• Uniform airflow across entire length

• Variable force and flow

• No moving parts - maintenance free

• Easy mounting - compressed air inlets

on each end and bottom

• Compact, rugged, easy to install

• Recessed hardware

• Stock lengths to 108" (2743mm) in

aluminum, 303 stainless steel, and 316

stainless steel (ss - for temperatures up

up to 800°F (427°C), food processing or

corrosive environments), and PVDF up to

54" (1372mm) for superior corrosion

resistance.

• Special lengths available

• Unlimited system lengths of uninterrupted

airflow available

Fast moving bottles are blown dry by (2) Model 110012 12" (305mm) Super Air Knives prior to labeling.

Model 110006 6" (152mm) Super Air Knife removes residual water from can bottoms after a rinse process, eliminating water damage to packaging and shipping materials.

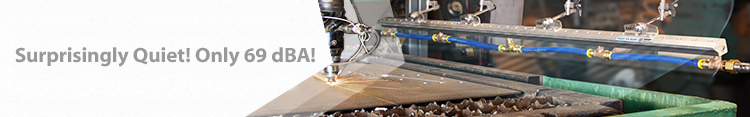

Model 110054 54" (1372mm) Super Air Knife dries stamped parts that exit a washer.

A Model 110048PKI 48" (1219mm) Super Air Knife with Plumbing Kit installed uses EXAIR’s Universal Air Knife Mounting System to maintain proper position for removing dust on a conveyor belt and eliminate carryover accumulation.

(3) Model 110012 12" (305mm) Super Air Knives blow excess honing oil off machined engine sleeves.

A Model 110018 18" (457mm) Super Air Knife cools molten plastic following dip molding.

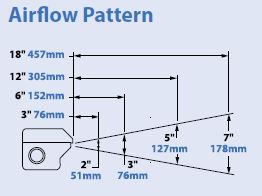

How The Super Air Knife Works

Compressed air flows through an inlet (1) into the plenum chamber of the Super Air Knife. The flow is directed to a precise, slotted orifi ce. As the primary airflow exits the thin slotted nozzle (2), it follows a flat surface that directs the airflow in a perfectly straight line. This creates a uniform sheet of air across the entire length of the Super Air Knife. Velocity loss is minimized and force is maximized as the room air (3) is entrained into the primary airstream at a ratio of 40:1. The result is a well defined sheet of laminar airflow with hard-hitting force and minimal wind shear.

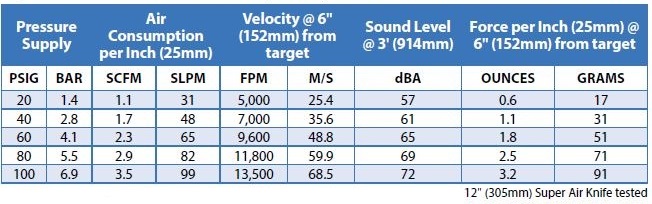

Super Air Knife Performance with .002" (0.05mm) thick shim installed

Super Air Knife Specifications

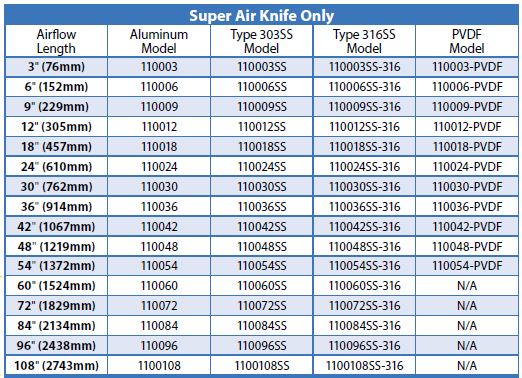

The Super Air Knife is available in standard lengths of 3", 6", 9" 12", 18", 24", 30", 36", 42", 48", 54", 60", 72", 84", 96" and 108" (76, 152, 229, 305, 457, 610, 762, 914, 1067, 1219, 1372, 1524, 1829, 2134, 2438 and 2743mm). Special lengths and unlimited system lengths are available. Any number of Super Air Knives may be installed across a given area.

Compressed Air Inlets: A Super Air Knife has compressed air inlets on each end and the bottom. Knives 24"-47" should use the 2 inlets at opposite ends of the knife. Knives 48"-59" use 2 inlets at opposite ends plus 1 near the middle on the bottom of the knife. Knives 60"-83" use 2 inlets at opposite ends plus 2 inlets equally spaced on the bottom of the knife. Knives 84" and longer use 2 inlets at opposite ends plus 3 inlets equally spaced on the bottom of the knife.

Filtration: The use of clean air is essential. Kits include an automatic drain filter with a 5 micron filter element that is sized properly for flow.

Materials of Construction: The Super Air Knife is available from stock in aluminum, Type 303 stainless steel, Type 316 stainless steel and PVDF. Other materials are available on special order.

Mounting: The Universal Air Knife Mounting System is available. The Super Air Knife can be supported by the compressed air pipe. Tapped holes (1/4-20) on the bottom are also provided.

Regulation: A pressure regulator on the compressed air supply provides infinite control of flow, force and air consumption. Kits include a pressure regulator that is sized properly for flow.

Shim Sets: The compressed air exhausts through a gap which is set with a shim. Force and flow may be increased by adding shims. Shim sets for aluminum Super Air Knives include a .001" (0.03mm) Amber color , .003" (0.08mm) Green color , and .004" (0.10mm) thick Tan color plastic shims. A Red color .002" (0.05mm) thick shim comes installed in the Super Air Knife. Shim sets for stainless steel Super Air Knives include (3) .002" (0.05mm) stainless steel shims. PVDF Super Air Knife shim sets include (3) .002" (0.05mm) PTFE shims.

Compressed Air Inlets: A Super Air Knife has compressed air inlets on each end and the bottom. Knives 24"-47" should use the 2 inlets at opposite ends of the knife. Knives 48"-59" use 2 inlets at opposite ends plus 1 near the middle on the bottom of the knife. Knives 60"-83" use 2 inlets at opposite ends plus 2 inlets equally spaced on the bottom of the knife. Knives 84" and longer use 2 inlets at opposite ends plus 3 inlets equally spaced on the bottom of the knife.

Filtration: The use of clean air is essential. Kits include an automatic drain filter with a 5 micron filter element that is sized properly for flow.

Materials of Construction: The Super Air Knife is available from stock in aluminum, Type 303 stainless steel, Type 316 stainless steel and PVDF. Other materials are available on special order.

Mounting: The Universal Air Knife Mounting System is available. The Super Air Knife can be supported by the compressed air pipe. Tapped holes (1/4-20) on the bottom are also provided.

Regulation: A pressure regulator on the compressed air supply provides infinite control of flow, force and air consumption. Kits include a pressure regulator that is sized properly for flow.

Shim Sets: The compressed air exhausts through a gap which is set with a shim. Force and flow may be increased by adding shims. Shim sets for aluminum Super Air Knives include a .001" (0.03mm) Amber color , .003" (0.08mm) Green color , and .004" (0.10mm) thick Tan color plastic shims. A Red color .002" (0.05mm) thick shim comes installed in the Super Air Knife. Shim sets for stainless steel Super Air Knives include (3) .002" (0.05mm) stainless steel shims. PVDF Super Air Knife shim sets include (3) .002" (0.05mm) PTFE shims.

Super Air Knife Models