Blowoff , dry, clean and cool pipe, cable, extruded shapes, hose, and wire!

Split design requires no threading!

- Uniform 360° Airfl ow!

- For Environments Up To 800°F

- Variable Force And Flow!

What Is The Super Air Wipe?

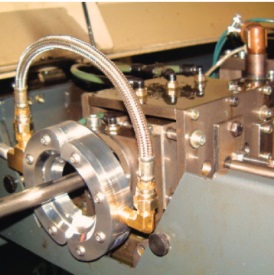

EXAIR’s Super Air Wipe provides a uniform 360° airstream that is ideal for blowoff , drying, cleaning and cooling of pipe, cable, extruded shapes, hose, wire and more. The split design offers easy clamping around the surface of the material moving through it, eliminating the need for threading. Available from 3/8" (10mm) through 11" (279mm) diameters. All models include stainless steel screws and shims. Stainless steel wire braided hose is also included on sizes up to 4" (102mm) for added corrosion and heat resistance. Aluminum models are rated for temperatures up to 400°F (204°C) and stainless steel models for temperatures up to 800°F (427°C).

Why The Super Air Wipe?

Prior to the introduction of the Super Air Wipe, the only way to blowoff , dry, clean and cool cylindrical, round, or extruded surfaces was to use a ring of air nozzles. The high air consumption and noise levels of the nozzles along with inconsistent air velocity often delivered poor results. Th e Super Air Wipe provides a high volume, high velocity airflow that is uniformly ejected from the 360° of its inner diameter. The airstream attaches itself to the material running through it to effectively wipe, clean or dry surfaces. Velocity can be varied from a “blast” to a “breeze”. Air consumption and noise are low.

Applications

• Drying after washing, cleaning, plating or coating

• Blowoff dust and contaminants

• Cool hot extruded shapes

• Uniformly wipe surfaces

• Dry extruded profiles, rod and medical tubing

• Eliminate solution carryover - no cross contamination

• Blow excess water from automotive door gaskets

• Remove excess coatings, water and oil

• Dry tube, hose, wire, fiber optics

• Minimize solution loss due to drag-out

• Clean paint gun tips

• Dry screen printed or ink jetted surfaces

• Clean strips and ribbon

Advantages

• Quiet

• Low air consumption

• Uniform 360° airflow

• Stainless steel hardware resists corrosion

• Aluminum models for temperatures up to 400°F (204°C)

Stainless steel models for temperatures up to 800°F (427°C)

• Stainless steel hose supplied on sizes up to 4" (102mm)

• No electricity, no moving parts

• Non-contact - no wiper blade

• Split design - compact, rugged, easy to install

• Lightweight, low profile

• Tapped holes for mounting

• Variable force and flow

• Meets OSHA maximum dead end pressure and noise requirements

• Low air consumption

• Uniform 360° airflow

• Stainless steel hardware resists corrosion

• Aluminum models for temperatures up to 400°F (204°C)

Stainless steel models for temperatures up to 800°F (427°C)

• Stainless steel hose supplied on sizes up to 4" (102mm)

• No electricity, no moving parts

• Non-contact - no wiper blade

• Split design - compact, rugged, easy to install

• Lightweight, low profile

• Tapped holes for mounting

• Variable force and flow

• Meets OSHA maximum dead end pressure and noise requirements

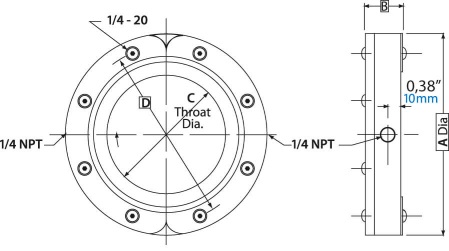

Air Wipe Dimensions

Air Wipe Performance

| 80 PSIG (5.5 BAR) |

Air Consumption |

Sound Level @3' (914mm) |

|

| MODEL # | SCFM | SLPM | dBA |

| 2399,2429 | 11.1 | 314 | 82 |

| 2400,2400SS,2430 | 13.9 | 394 | 80 |

| 2401,2401SS,2431 | 19.1 | 541 | 80 |

| 2402,2402SS,2432 | 29.5 | 835 | 81 |

| 2403,2403SS,2433 | 39.8 | 1,127 | 82 |

| 2404,2404SS,2434 | 50.2 | 1,422 | 82 |

| 2405, 2435 | 60.6 | 1,716 | 82 |

| 2406, 2436 | 71.0 | 2,010 | 84 |

| 2407, 2437 | 81.3 | 2,302 | 85 |

| 2409, 2439 | 102.1 | 2,891 | 87 |

| 2411, 2441 | 122.8 | 3,477 | 89 |

| Super |

Std |

A |

B |

C |

D |

|

| 2399 | 2429 | in | 3.13 | 1.13 | 0.38 | 2.38 |

| mm | 79 | 29 | 10 | 60 | ||

| 2400,2400SS | 2430 | in | 3.25 | 1.13 | 0.50 | 2.50 |

| mm | 83 | 29 | 13 | 64 | ||

| 2401, 2401SS | 2431 | in | 3.75 | 1.13 | 1 | 2.95 |

| mm | 95 | 29 | 25 | 75 | ||

| 2402, 2402SS | 2432 | in | 4.75 | 1.13 | 2 | 3.95 |

| mm | 121 | 29 | 51 | 100 | ||

| 2403, 2403SS | 2433 | in | 5.75 | 1.13 | 3 | 4.95 |

| mm | 146 | 29 | 76 | 126 | ||

| 2404, 2404SS | 2434 | in | 6.75 | 1.13 | 4 | 5.95 |

| mm | 127 | 29 | 102 | 151 | ||

| 2405 | 2435 | in | 7.75 | 1.13 | 5 | 6.95 |

| mm | 197 | 29 | 127 | 176 | ||

| 2406 | 2436 | in | 8.75 | 1.13 | 6 | 7.95 |

| mm | 222 | 29 | 152 | 202 | ||

| 2407 | 2437 | in | 9.75 | 1.13 | 7 | 8.95 |

| mm | 248 | 29 | 178 | 227 | ||

| 2409 | 2439 | in | 11.75 | 1.13 | 9 | 10.95 |

| mm | 299 | 29 | 229 | 278 | ||

| 2411 | 2441 | in | 13.75 | 1.13 | 11 | 12.95 |

| mm | 349 | 29 | 279 | 329 | ||

Super Air Wipe Specifications

The Super Air Wipe is available with throat diameters (I.D.) of 3/8", 1/2", 1", 2", 3", 4", 5", 6", 7", 9", and 11" (10, 13, 25, 51, 76, 102, 127, 152, 178, 229, and 279mm). Special diameters are available.

Compressed Air Inlets:

The Super Air Wipe has compressed air inlets on each half. Stainless steel wire braided hose is supplied with sizes up to 4" (102mm) that couples the air supply of one half to the other. Sizes 9" (229mm) and larger have two inlets on each half that must be supplied with compressed air to maintain uniform airflow.

Temperature:

Aluminum Super Air Wipes are rated for temperatures up to 400°F (204°C). Stainless steel models are rated for temperatures to 800°F (427°C).

Filtration:

Th e use of clean air is essential. Kits include an automatic drain filter separator with a 5 micron filter element that is sized properly for flow.

Mounting:

The Super Air Wipe can be supported by the compressed air supply pipe. Tapped holes (1/4-20) on the downstream side of the Super Air Wipe can also be used for mounting.

Materials of Construction:

The Super Air Wipe is constructed of aluminum or stainless steel. All models use stainless steel shims and screws. Stainless steel wire braided hose is included with sizes up to 4" (102mm).

Regulation:

A pressure regulator on the compressed air supply provides infinite control of flow, force and air consumption. Kits include a pressure regulator that is sized properly for flow.

Shim Sets:

The Super Air Wipe has a .002" (0.05mm) gap setting. The compressed air exhausts through a gap which is set with a stainless steel shim positioned between the cap and body of the Super Air Wipe. Force and flow through the Super Air Wipe may be easily increased by adding shims to open the gap. Kits include a shim set. Shim sets include (2) .002" (0.05mm) thick stainless steel shims.

Changing Performance By Adding Shims

The compressed air exhausts through a gap which is set with a shim positioned between the cap and the body of the Super Air Wipe. The Super Air Wipe is shipped with a .002" (0.05mm) thick stainless steel shim installed which works best for most applications. Force and fl ow may be easily increased by adding shims to open the gap. Increasing the gap opening off ers higher velocity and harder hitting force. Air consumption and noise will be slightly higher. Super Air Wipe shim sets include two .002" (0.05mm) stainless steel shims that can be stacked. Shim sets are included with all kits or can be purchased separately.

| Super Air Wipe Models | |||||

| Super Air Wipe Only Super Air Wipe Kits - include the Super Air Wipe, shim set, filter separator and pressure regulator (with coupler). Super Air Wipe Shim Sets - include (2) .002" (0.05mm) thick stainless steel shims. |

|||||

|

I.D. |

Aluminum Super Air Wipe Only Model |

Aluminum Super Air Wipe Kit Model |

Stainless Steel Super Air Wipe Only Model |

Stainless Steel |

Super Air Wipe |

| 3/8" (10mm) | 2399 | 2449 | N/A | N/A | 2349SS |

| 1/2" (13mm) | 2400 | 2450 | 2400SS | 2450SS | 2350SS |

| 1" (25mm) | 2401 | 2451 | 2401SS | 2451SS | 2351SS |

| 2" (51mm) | 2402 | 2452 | 2402SS | 2452SS | 2352SS |

| 3" (76mm) | 2403 | 2453 | 2403SS | 2453SS | 2353SS |

| 4" (102mm) | 2404 | 2454 | 2404SS | 2454SS | 2354SS |

| 5" (127mm) | 2405 | 2455 | N/A | N/A | 2355SS |

| 6" (152mm) | 2406 | 2456 | N/A | N/A | 2356SS |

| 7" (178mm) | 2407 | 2457 | N/A | N/A | 2357SS |

| 9" (229mm) | 2409 | 2459 | N/A | N/A | 2359SS |

| 11" (279mm) | 2411 | 2461 | N/A | N/A | 2361SS |

| Accessories | |||||

| Model# | Description | ||||

| 9001 | Auto Drain Filter Separator, 3/8 NPT, 65 SCFM (1,841 SLPM) | ||||

| 9032 | Auto Drain Filter Separator, 1/2 NPT, 90 SCFM (2,549 SLPM) | ||||

| 9002 | Auto Drain Filter Separator, 3/4 NPT, 220 SCFM (6,230 SLPM) | ||||

| 9005 | Oil Removal Filter, 3/8 NPT, 15-37 SCFM (425-1,048 SLPM) | ||||

| 9006 | Oil Removal Filter, 3/4 NPT, 50-150 SCFM (1,416-4,248 SLPM) | ||||

| 9008 | Pressure Regulator, 1/4 NPT, 50 SCFM (1,416 SLPM) | ||||

| 9033 | Pressure Regulator, 1/2 NPT, 100 SCFM (2,832 SLPM) | ||||

| 9009 | Pressure Regulator, 3/4 NPT, 220 SCFM (6,230 SLPM) | ||||

| 9020 | Solenoid Valve, 120V, 50/60Hz, 1/4 NPT, 40 SCFM (1,133 SLPM) | ||||

| 9034 | NEMA 4/4X Solenoid Valve, 120V, 50/60Hz, 1/2 NPT, 100 SCFM (2,832 SLPM) | ||||

| 9036 | NEMA 4/4X Solenoid Valve, 120V, 50/60Hz, 3/4 NPT, 200 SCFM (5,664 SLPM) | ||||