Saving Money and Compressed Air

Air consumption, force and noise level are shown for each of EXAIR's Nozzles and Jets that you will see on our web site.

Consider the following example where a Model 1102 Mini Super Air Nozzle replaces a 1/8" (3.2mm) open pipe. The compressed air savings is easy to calculate and proves to be dramatic. Payout for Air Nozzles and Jets, including filter and installation cost is measured in weeks - not years as is the case for other cost reduction equipment. Based on a 40 hour week, 52 weeks a year.

Example:

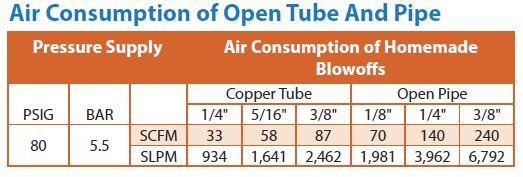

Existing blowoff is 1/8" (3.2mm) open pipe at 80 PSIG (5.5 BAR) supply. Air consumption, from the table above is 70 SCFM (1,981 SLPM).

Use a 1/8 FNPT Model 1102 Mini Super Air Nozzle also at 80 PSIG (5.5 BAR) supply. Air consumption for a Model 1102 Mini Super Air Nozzle is 10 SCFM (283 SLPM). (To see the air consumption of all of our Nozzles and Jets, see the Air Nozzles and Jets "Quick Pick" Comparison.)

Compressed air saved =70 - 10 = 60 SCFM (1,981 - 283 =1,698 SLPM)

For this example, the blowoff is continuous. If the duty cycle was 20%, then air saved would be 60 x .2 = 12 SCFM (1,698 x .2 = 340 SLPM)

Most large plants know their cost per 1,000 standard cubic feet of compressed air (10,000 standard liters). If you don't know your actual cost per 1,000 SCF, Rs is a reasonable average to use. (Cost per 10,000 standard liters is approximately $0.089.)

Dollars saved per hour = SCFM saved x 60 minutes x cost/1,000 SCF (SLPM saved x 60 min x cost/10,000 SL)

= 60 x 60 x .25/1,000 (= 1,698 x 60 x $0.089/10,000)

= $0.90/hour

$0.90/hr. is $36.00/week and

$1,872.00/year savings for One nozzle!