Air saving Gen4 Ion Air Jet is an effective spot cleaner!

Choose permanent mount or flexible hose with base!

Choose permanent mount or flexible hose with base!

What Is The Gen4® Ion Air Jet?

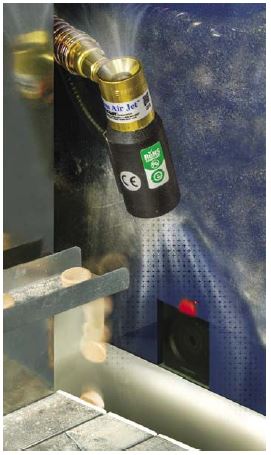

EXAIR's Gen4 Ion Air Jet delivers a concentrated airflow that can cover a precise spot without disturbing other areas. Th[is quiet, focused airstream provides incredibly fast static decay rates and cleaning ability. The Gen4 Ion Air Jet is the ideal way to remove static and dust from small parts prior to shrink wrapping, packaging,

printing, painting or fi nishing.

printing, painting or fi nishing.

Why The Gen4® Ion Air Jet?

The Gen4 Ion Air Jet induces surrounding airflow at a ratio of 5:1, minimizing compressed air use and maximizing ionized airflow. Force can be adjusted from a “blast” to a “breeze”.

Your Choice Of Permanent Mount or Flexible Stay Set Hose™

For permanent mount applications, the compact Gen4 Ion Air Jet is the best choice since it is lightweight and easy to install using the 1/8 NPT male inlet. For applications where frequent repositioning is required, the flexible Gen4 Stay Set Ion Air Jet™ is ideal. Th is version can be placed in close proximity and the hose bent to aim the ionized airstream at the localized area. Since the hose has “memory” it will not creep or bend, always keeping the aim until physically moved to the next position.

The Gen4 Stay Set Ion Air Jet comes complete with a magnetic base that allows easy mounting and portability on a machine, a bench or other surface. A shutoff valve on

the base provides infinite control of the force and flow. For hands free operation, an optional Model 9040 Foot Pedal (requires floor or machine mounting) is available.

The Gen4 Stay Set Ion Air Jet comes complete with a magnetic base that allows easy mounting and portability on a machine, a bench or other surface. A shutoff valve on

the base provides infinite control of the force and flow. For hands free operation, an optional Model 9040 Foot Pedal (requires floor or machine mounting) is available.

Applications

•Three dimensional parts

• Bottle cleaning

• Screen printing

• Shrink bands

• Ink jet printing

• Part cleaning

• Package cleaning

•Three dimensional parts

• Bottle cleaning

• Screen printing

• Shrink bands

• Ink jet printing

• Part cleaning

• Package cleaning

Advantages

• Low cost

• Rapid static decay

• Low cost

• Rapid static decay

• Quiet • Shockless, non-radioactive

• Electromagnetically shielded high

voltage cable

• Armored high voltage cable protects

against abrasion, cuts

• Integrated ground design requires no

separate ground connection

• Replaceable emitter point

• Compact, rugged, easy to install

• Stay Set Hose for accurate placing

• Low air consumption

• Electromagnetically shielded high

voltage cable

• Armored high voltage cable protects

against abrasion, cuts

• Integrated ground design requires no

separate ground connection

• Replaceable emitter point

• Compact, rugged, easy to install

• Stay Set Hose for accurate placing

• Low air consumption

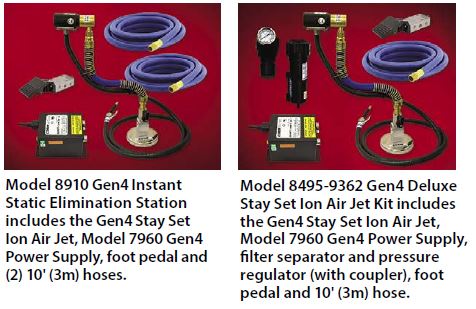

The Model 8194-9362 Gen4 Stay Set Ion Air Jet Kit cleans dust from a glass lens prior to installation on a gauge..

The Gen4 Model 8910 Instant Static Elimination Station removes contaminants on plastic fittings prior to packaging.

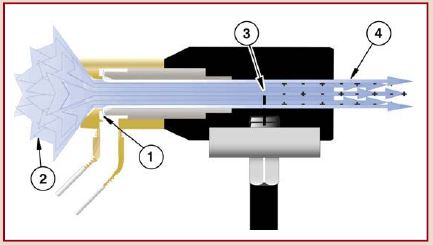

The Gen4 Ion Air Jet incorporates a High Velocity Air Jet and electrically energized emitter point. A small amount of compressed air is injected into the air jet (1) inducing high volume flow of surrounding air (2) to pass through it.

The emitter point (shockless) at the discharge end of the gun (3) ionizes the entire airstream. The result is a high volume flow of ionized air (4) capable of neutralizing

high static charges in fractions of a second. An optional filter and regulator clean the compressed air and allow infinite adjustment of airflow and velocity.

The emitter point (shockless) at the discharge end of the gun (3) ionizes the entire airstream. The result is a high volume flow of ionized air (4) capable of neutralizing

high static charges in fractions of a second. An optional filter and regulator clean the compressed air and allow infinite adjustment of airflow and velocity.

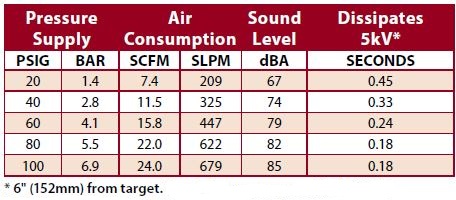

Gen4® Ion Air Gun Performance

Gen4® Ion Air Jet Specifications

EXAIR Model 7960 or 7961 Gen4 Power Supply (5kV) is required for Ion Air Jet operation.

Certifications: Gen4 Ion Air Jet and Gen4 Power Supplies are UL Component Recognized to U.S. and Canadian safety standards, and are CE and RoHS compliant.

Electrical: For use with 5 kVrms, 5 milliamperes (max.) power supply.

Electrical Hazard: shockless (less than 40 microamperes short circuited).

Do not use near flammable materials or gases.

Materials of Construction:

Metal Parts: Aluminum

Plastic Parts: UL rated 94 HB

Emitters: Stainless Steel

Maximum Ambient Temperature: 165°F (74°C)

Shims: Thicker shims can be installed easily if additional hard-hitting velocity is required.

Compressed Air: 1/8 NPT inlet provided on Gen4 Ion Air Jet.

1/4 NPT inlet provided on Gen4 Stay Set Ion Air Jet.

Certifications: Gen4 Ion Air Jet and Gen4 Power Supplies are UL Component Recognized to U.S. and Canadian safety standards, and are CE and RoHS compliant.

Electrical: For use with 5 kVrms, 5 milliamperes (max.) power supply.

Electrical Hazard: shockless (less than 40 microamperes short circuited).

Do not use near flammable materials or gases.

Materials of Construction:

Metal Parts: Aluminum

Plastic Parts: UL rated 94 HB

Emitters: Stainless Steel

Maximum Ambient Temperature: 165°F (74°C)

Shims: Thicker shims can be installed easily if additional hard-hitting velocity is required.

Compressed Air: 1/8 NPT inlet provided on Gen4 Ion Air Jet.

1/4 NPT inlet provided on Gen4 Stay Set Ion Air Jet.